Optical Blueberry Sorting just took a huge leap forward.

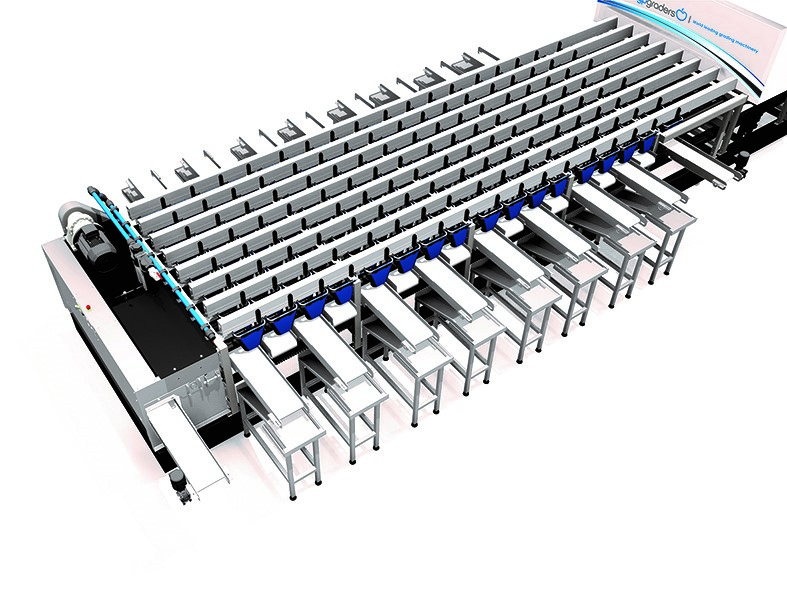

The first Australian installation of the GP Graders AirJet® optical sorter for Blueberries was installed in Woolgoolga last season and has proved a huge asset to its owner.

“The GP Graders Airjet® has allowed us to double our output with half the staff, it’s incredible”, we wouldnt have got through the season without it!" says Bob Benning.

Designed in Melbourne by GP Graders, with Australian conditions in mind, it has the ability to sort by up to 5 levels of softness, colour, defects, Rust, Hail Damage, Frost Damage, stems on, splits, healed over splits.

Smarter, Faster, Gentler than any other grader on the market.

The AirJet® blueberry grading line has been designed for full sanitation washdown after use. All parts of the machinery have been developed for cleaning accessibility and the machine has its own self washing cycle which washes and dries the conveyor at the press of a button.

A&B Packing and GP Graders are working together to provide the

most reliable, easy to use, best value for money packhouse solutions in the world.

Blueberry Evolutions

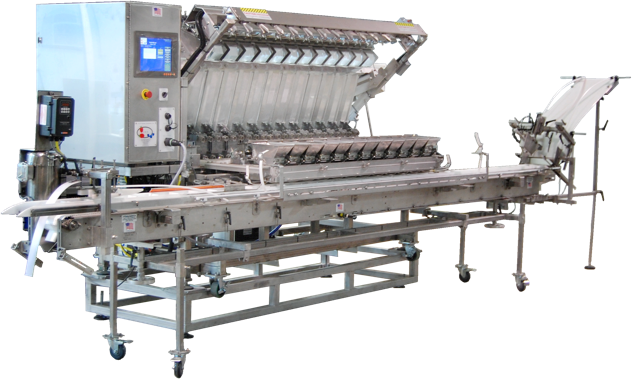

The Evolution G2 is A & B Packing’s flagship machine, It is available in 4, 6, 10 and 12 and

16 lane models offering a range of speeds. The specially designed bombay doors ensures gentleness,reducing drop impact by up to 60% over our competitors method. With an inbuilt punnet denester and closer to pack up to 240 punnets per minute with extreme accuracy.

A&B Packing builds weigh and fill machines to suit all capacities and budgets

4 Scale - 60 per min

6 Scale - 90 per min

12 Scale 180 per min

16 Scale - 240 per min

Evolution Cleaning and Maintenance

The Evolution is the only weigh and fill on the market that opens up to allow easy cleaning and maintenence.

The scale hoppers are simple to remove and can be cleaned off the machine Cleaning the line takes about 10 mins at the end of the day.

© Impact Automation 2019 | info@impactautomation.com.au